Nano Crystallized Glass Stone Panel Slabs

Factory Direct, Competitive Prices, specular gloss over 95 degrees

Pure white slab and super black slab

Size: 2800x1600, 3200x1600, 3000x1500mm

Thickness: 12mm, 18mm, 30mm

Customization of thickness and size

3D Inkjet Pringting NanGlass Stone Panels

Size: maximum width 1600mm

Thickness: 12mm, 18mm.

Customization of patterns based on design drawing

Nanoglass Countertops

Costomization of size and shape as demanded.

hot bending, special-shaped, etc.

Nano Crystallized Stone is a specialized, advanced form of engineered stone, known for its enhanced durability and aesthetic qualities.

5000+

Daily Output

200+

Finished Projects

50+

Agency Partners

10+

Industry Experience

HS CODE: 7006000090; (No anti-dumping Tax!)

USA HTS: 7006.00; ( No anti-dumping Tax!)

Loading Port: Xiamen Port,China

Features of Nano Crystallized Glass Stone

Transparent more beautiful and fancier

Uniform and Natural Effect of Light Transmission

Infinite Length freer and more flexible

Optional Specifications

Hot Bending new ornaments, new ideas

Bent Freely to Form Curved Plates and Profiles

Repairable long service life and easy care

Mohs 6 of Hardness; Flat and No Scratches

Environmental Protection safe and guaranteed

100% Natural and Recyclable Materials

Wide Application wide-range in application and guaranteed quality

Wall, Floor Covering and Surface Material of Furniture .

Nano Glass Slabs - Sufficient Stock, Guaranteed Delivery

The daily output of Nano Crystallized Glass Large Stone Slab is more than 4,500 square meters, equipped with a warehouse of 50,000 square meters. We have sufficient stocks of Nano Crystallized Glass Stone Large Slabs, which can be delivered to the designated location within the designated time as buyer's request.

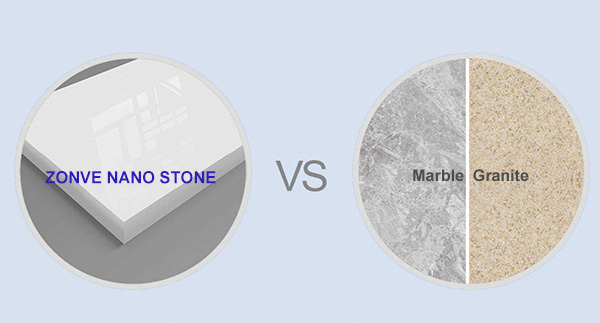

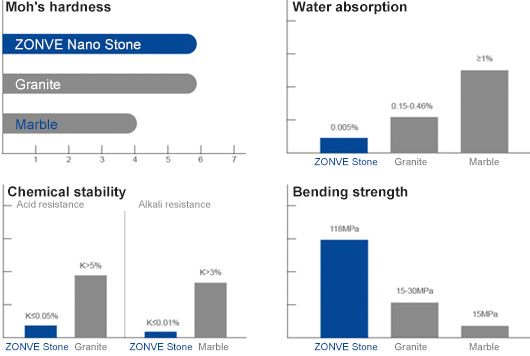

Nano Stone VS Nautre Stone

| Performance | ZONVE Nano Stone | Others’ Nano Stone | Marble | Granite |

| Bending strength (MPa) | >100 | 55 | 6.7-20 | 9-24 |

| Compressive strength (Mpa) | >600 | 280 | 67-100 | 100-200 |

| Moh's hardness | >6 | 6 | 3.5-4 | 6 |

| Water absorption (%) | 0.002 | 0.005 | 0.3 | 0.35 |

| Acid resistance (%) (1% sulfuric acid) | >99 | >95 | >90 | >93 |

| Alkali resistance (%) (1% sodium hydroxide) | >99 | >95 | >93 | >93 |

| Gloss | ≥97 | ≥90 | ≥85 | ≥85 |

Engineered stone offers a versatile and durable alternative to natural stone, combining aesthetics with practicality for modern design needs

Team of ZONVE Nano Stone Co.,

ZONVE has 7 senior managers with working backgrounds in large state-owned enterprises, central enterprises or listed companies, and more than 20 Nano Crystallized Glass stone technical talents. At present, the organization is complete, the system process is standardized, and the mechanism is perfect.

Zhongjun Zhuangyi New Materials Co., Ltd have cooperated closely with many universities, some of which have reached cooperation with teaching, research, production and education bases. In addition, we have more than 50 independent patents. Talents and resources are continuously gathered.

Video of ZONVE Nano Glass Stone

00:16 Introduction

00:55 Production Process

01:37 An excellent alternative to nature marble

02:03 Inkjet process

02:39 Nanoglass Countertops Processing

02:59 Hot bending technique

03:18 Project cases

03:58 Cooperation and Contact

>> INQUIRY <<

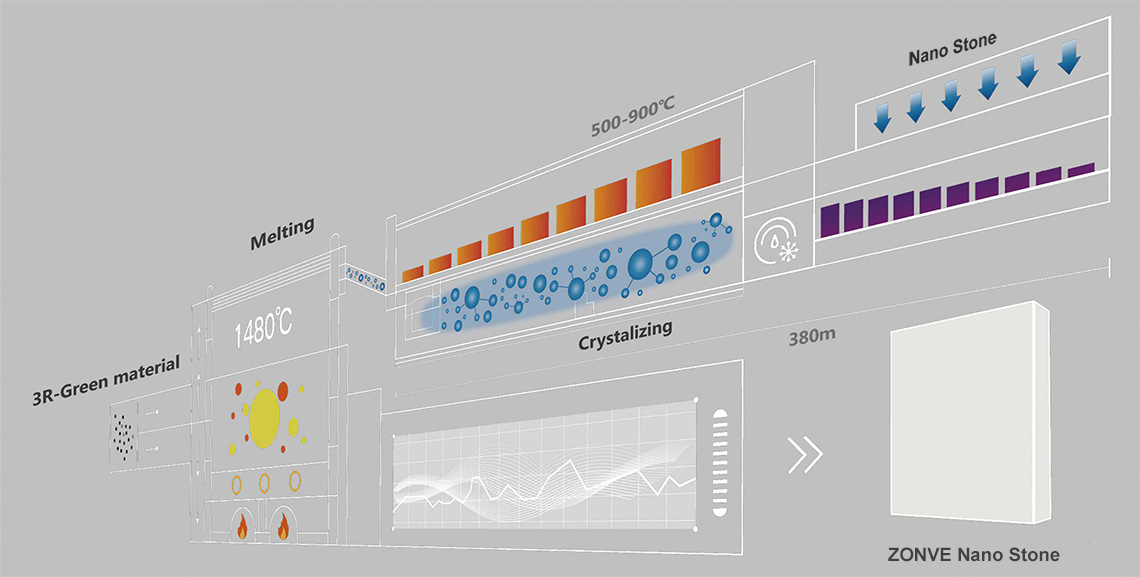

Production of Nano Glass Slabs

ZONVE Nano Crystallized Glass Stone Slabs Manufacture Co., Ltd.(ZHONGJUN ZHUANGYI NEW MATERIALS CO., LTD) is committed to solving the problem of research, and promotes the reuse of industrial solid waste and tailings. Besides, the company continuously looks for new green materials. It is an environmentally friendly and high-tech enterprise in the whole industrial. ZONVE integrates R & D, production, processing and sales. At present, the production bases include: Hunan, Fujian, Guangxi and Shanxi. ZONVE is a new environmentally-friendly manufacturer of materials with advanced and super large production capacity in China.

Technical principle

The raw material of Nano Crystallizes Glass Stone is mainly quartz sand, which simulates the deposition of volcanic lava for thousands of years. It is smelted at 1600 degrees, and the molecular chain is reformed to form a new generation of high-tech and environmentally-friendly building materials.

Engineered stone, created from a blend of natural aggregates and resin, is renowned for its resistance to scratches, stains, and heat, making it ideal for kitchen and bathroom surfaces.

Tags in this page

-

Nano Glass Slabs

- Nano Crystallized Glass Stone

- Nano Crystallized Glass Stone Panel

- Crystallized Glass Stones

- Nano Crystallized Glass Stone panel Slabs

- Nano Crystallized Glass Stone Panels Polished Slab

- Nano glass white Crystallized Glass Stone panel

- Nano Glass Large Panels

More Tags

-

Artificial Nano Glass Slab Panels

- nano glass white Crystallized Glass Stone panel nanoglass

- Crystallized Glass Stone

- 3d Printing Nano Crystallized Glass Stone

- Crystallized Glass Stone Panels

- Crystallized Glass Stone Tile

- Pure White Nano Crystallized Glass Stone Panels

- Nano Glass Large Panels

The popularity of engineered stone in interior design stems from its ability to mimic the beauty of natural stone while providing enhanced functionality and easier maintenance.